Vendor Managed Inventory Has The Following Benefits

Mar 18, 2016 Yet, many OEMs don’t manage their inventory in the most cost efficient way possible. Fortunately, there’s an easy fix for making sure your inventory doesn’t arrive too late (or too early) to your factory floor: a vendor managed inventory (VMI) strategy. Vendor-Managed Inventory (VMI): What is it and When Does It Make Sense to Use It. By Dave Piasecki. Let’s look at some potential benefits to the vendor. As an inventory management consultant, I get exposed to a lot of bad inventory management practices. The truth is very few businesses are good at inventory management, and some are. In vendor-managed inventory, a company turns to its suppliers to determine when to restock its shelves based on retailer data and the vendor's own forecasting of customer demand. This presents a host of benefits to a company, from reduced inventory carrying costs to a shortened supply chain.

Vendor-managed inventory (VMI) is not a new concept, but it’s one that many merchants still do not adopt as part of their business strategy. Yet, when executed correctly, a vendor-managed inventory strategy can bring huge benefits to your business.In this post, we’ll summarize what exactly VMI is.

Then, we’ll discuss vendor-managed inventory benefits you can expect to experience with a well-run program.The goal is for you to understand what your business can be with VMI and what you have to do next.Vendor-Managed Inventory DefinitionPut simply, vendor-managed inventory is a process where the supplier (or the next party, up the supply chain) manages your inventory instead of you. It can be an extremely effective strategy, when executed correctly–this is what made Walmart the behemoth it is today. Traditional Inventory ManagementLet’s say you’re a retailer who sells widgets that are manufactured by ABC Widget Co.

In a traditional business model, you will forecast your sales, then order enough widgets from ABC to fulfill the sales your forecasted.This traditional inventory management model is challenging in a few ways:. The accuracy of your forecast is limited, so you risk buying too much or too little stock. You purchase and own the inventory, regardless of whether you sell it. You have limited visibility into whether your supplier can even fulfill your order.It’s common business knowledge that excess inventory is a liability, but it’s also common that you can’t sell what you don’t have. Traditional inventory management approaches can force you to purchase excess inventory to pad yourself against stock-outs, causing you to carry excess.

You literally have to decide what’s less bad for your business: running out of inventory or carrying too much. Vendor-Managed InventoryVendor-managed inventory relationships attempt to solve these problems by sharing the burden of inventory management between the buyer and the seller. (In our example, the manufacturer is the seller and the retailer is the buyer.). The goal with a vendor-managed inventory relationship is to make sure the retailer only buys what they’ll sell.

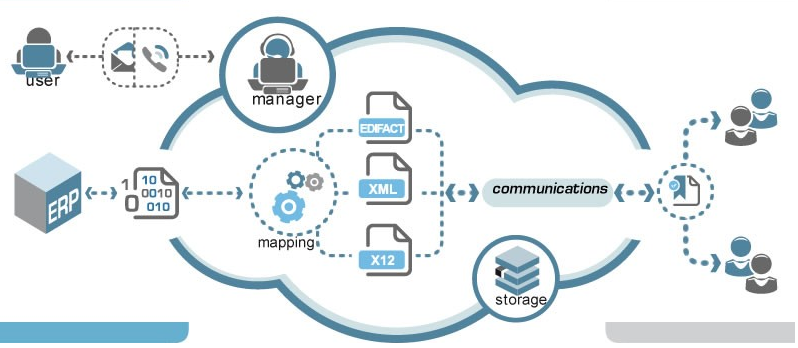

They maintain closer contact with the supplier, aided by technology, so that they can purchase stock in smaller batches, more frequently.Most importantly, the burden of inventory management is shifted to the seller (the manufacturer in our example), who pushes inventory down to buyers, based on real-time demand.Instead of forecasting quarterly sales, and buying a whole bunch of widgets to ensure those sales can be made, the retailer will be in constant communication with ABC Widget Co. (the manufacturer). The retailer constantly pushes their inventory counts to the manufacturer, who constantly maintains the retailers stock, making frequent, smaller shipments of product.Typically the vendor-managed inventory process is facilitated with modern communication technology. Click to enlarge this infographic showing the benefits of VMI.When the companies in a supply chain create well-run vendor-managed inventory relationships, basically everyone involved benefits. Let’s take a look at some of those benefits.

Share this Infographic On Your SitePlease include attribution to nChannel with this graphic. Benefits to the CustomerAt the end of every supply chain is a customer (often a consumer, sometimes a business) who will actually use the product. They have basically no control over the supply chain, but they have a very powerful role at the end of it. If they don’t buy, no one up the chain makes money.It’s important to understand how vendor-managed inventory benefits the customer, because at the end of the day, if they aren’t winning, no one is. Improved Customer ExperienceThe vendor-managed inventory program ensures that the retailer–the organization selling to the end customer–always has just the right amount of stock.

And, having the right amount of stock isn’t just a financial advantage.Let’s say I’m looking for a necklace for my wife for our anniversary. Of course, I procrastinated and I need to find one right away. I check your website and find one I like, but I want to see it in the store before I buy.Unfortunately, when I arrive at the store, the salesperson informs me that it’s out of stock in their store and it will take 2 weeks to come in.This is not good for me. This means I cannot and will not buy from you. And, because my experience with your brand wasn’t good, I’m not likely to shop at your store next time.Ensuring you have that inventory in stock creates a better experience for your customer.

When the customer needs to rely on you for something, you’re there to oblige. Positive customer experiences encourage repeat purchases and brand advocacy.Happy customers make happy retailers.

.jpg)

Better Manufacturer KnowledgeWhen a customer buys a product, they often have questions about the basics of how it was built. Was it built in the U.S.A.? Was it built using sustainable processes and products?

Does the manufacturer pay a living wage to all employees?These aren’t the kinds of questions retailers had to be ready to field just a decade or two ago. A vendor-managed inventory solution helps retailers share this information with customers, because of the much closer relationship between the retailer and the manufacturer.This is really just a spin on better customer experience. Customers want to trust the brands they buy.

They are for quality products and open production. The customer views a closer relationship with a retailer and the rest of the supply chain as a benefit. And, they will reward you with loyalty and repeat purchases. Benefits to the Retailer or DistributorThe retailer or distributor might be the party who benefits most of all from a vendor-managed inventory approach, because it reduces their risk of holding inventory. Obviously, retailers and distributors have very different business models, but their VMI benefits are similar, so I lumped them together here.

Fewer Stock-OutsWith a vendor-managed inventory relationship, the retailer/distributor should rarely run out of stock, because the retailer is less likely to under purchase in order to avoid excess stock.Retailers are constantly walking a tight-rope: excess inventory versus missing sales due to stock-outs. They depend on forecasting methodologies that are sometimes no better than educated guesses. They have to make extra purchases to really make sure they don’t run out of product.When the vendor has close, frequent visibility into the retailer’s stock, it can push smaller deliveries of exactly what the retailer needs, before it runs out of stock. This tight relationship significantly reduces the risk that the retailer will run out. Increased Inventory Turn (Less Inventory)In a vendor-managed inventory relationship, the retailer/distributor doesn’t need to hold as much inventory to ensure they can fulfill orders or sales. This means they reduce the financial liabilities of inventory and improve the closely managed inventory turnover ratio (sales ÷ average inventory).Inventory costs the retailer money. When cash is used to purchase inventory (that may never sell), that cash can’t be used to operate the business or invest in other growth opportunities.

Every retailer wants to hold as little inventory as possible without running out, and that’s a tough balancing act.In a vendor-managed inventory relationship, the vendor pushes inventory down to the retailer in smaller batches, more frequently, based on how quickly the items are selling. It distributes the inventory risk, so it is shared betqween the buyer and seller. It gets the retailer as close as possible to buying exactly the amount of inventory that will sell. Benefits to the ManufacturerAll the way at the top of the supply chain, the manufacturer also benefits from an vendor-managed inventory relationship.

Improved Forecasting AbilityThink about how difficult it is for a manufacturer to forecast how much product to make. The ultimate driver should be how many consumers (or end customers) will buy, but the manufacturer is often separated by the customer by a few degrees–by layers of retailers and distributors.A vendor-managed inventory solution links the entire supply chain, effectively giving the manufacturer, at one end of the chain, direct visibility into the retailer’s sales data, at the other end. With actual customer sales data, manufacturers are able to more accurately predict how much to product to manufacture.

More Accurate Ordering and FulfillmentOrder fulfillment can be a big liability for manufacturers. If they make the wrong thing, send the wrong thing, make too much of the wrong thing, etc., it costs the manufacturer money. In traditional supply chain relationships, ordering and fulfillment can be rife with errors.The vendor-managed inventory relationship reduces the risk of errors in ordering and order fulfillment, mostly because it digitizes the processes. Systems talk to one another directly, even across company lines, instead of people. Humans make mistakes. Computers only make mistakes when humans force them to. Benefits to EveryoneFinally, there are benefits that are shared across all parties in the supply chain, from the top to the bottom. More Stable Supply ChainIn a supply chain, all parties are linked.

When something goes wrong in one spot, the ripple effect can impact many different organizations. For example, if a manufacturer has to shift focus to fill an emergency order for one customer, how many other customers are they delaying? You may be sharing risk with other companies you aren’t even aware of.When the entire supply chain is linked, using vendor-managed inventory relationships, the supply chain stabilizes.

It reduces the risk of major disruptions that can affect all the different companies that are linked directly and indirectly through the supply chain. Closer PartnershipsThe vendor-managed inventory strategy requires organizations to link their business processes and their technology platforms more closely. Ultimately, that means they are linking their businesses together, creating closer business partnerships.When companies pool their resources, their talented employees, and their energy, all in the pursuit of shared goals, everyone benefits. These partnerships can produce more innovative solutions for consumers (or end customers) at lower costs. Cooperative business is a win for everyone involved, and vendor-managed inventory relationships are one manifestation of improved partnership. What To Do NextIf implementing vendor-managed inventory processes with your suppliers or manufacturers sounds like the right strategic direction for you business, you can start with a few actions.First, try to calculate the value you believe a vendor-managed inventory solution can create for your business. If you were able to reduce your inventory by 50%, how would that impact your business?

If you were able to eliminate stock-outs, how much more revenue would you generate? Understanding the potential benefit to VMI will help you monitor the eventual ROI.Second, talk with your suppliers about improving your relationship. Even before you have technology-integrated inventory relationships, you’ll want to work closely with them. Make sure you are both on the same page. Make sure your suppliers are ones you feel comfortable building a longer-term, closer relationship with.Third, start looking for the right technology. Traditionally, VMI solutions have been driven by EDI technology, but also consider newer solutions that use more modern communication protocols.Finally, check out nChannel’s, part of the nChannel AppSuite, if you’re looking for a way to link your supply chain like never before.

We understand that we may not be right for everyone, but the conversation will be worth your time.

. sharesEditor’s Note: Cerasis is a. So why do we feature content related to Vendor Managed Inventory? In a VMI model, part of the equation is the inbound & outbound flow of the inventory.

Inventory is then put on pallets and shipped as freight. Distributors will inbound to a manufacturer the inventory needed and transportation management, especially inbound freight management, efficiency is paramount to an effective vendor managed inventory model. If you are looking to optimize VMI in regards to transportation management, or read our.As you may or may not know, Cerasis is.

Each blog post written is distributed into groups that reach the supply chain community as well as professionals in manufacturing, transportation, distribution, and more. Today’s post is a follow up blog post to the post written a week or so back called “Vendor Managed.” The post is also in response to a LinkedIn user, named, and long time commentator on Cerasis content.

Higo said in response to the VMI for Supply Chain Cost Reductions post was:“Very informative article, thank you. BTW, as far as I know, there are some various models such as: 1) stocks are nearby customer’s production line, and the supplier periodically checks it and fill up if necessary, 2) stocks are in the customer’s warehouse, and the supplier gets the information (consumption) and then fill up if necessary, 3) stocks are in the supplier’s warehouse (the customer owns, the stock level is contracted), and the supplier fills up when shipped, etc. So, I hope the next article explains the evolved VMI model.” Vendor Managed Inventory Model: A Quick Back StoryWhen I was Materials Manager at Maricopa County, Arizona, the second largest county in the country, I introduced Vendor Managed Inventory. I took our line of fasteners: bolts, nuts screws and washers and put them in one location in the Warehouse. I called Fastenal, who specializes in Vendor Managed Inventory (VMI) for fasteners, in to see what we can do together.

Vendor Managed Inventory Has The Following Benefits List

VMI is all about collaboration. We came to the conclusion, that each fastener type be put in a slot in a special rack that Fastenal gave us. We only paid for fasteners as we used them. There was a signed contract with agreed upon inventory levels. No Purchase Orders were used. There was no inventory carrying costs or concern for inventory turns. Fastenal would come in each week, check our inventory levels, and re-fill the rack based on agreed upon inventory amounts.

We never ran out of or had too much inventory. The Evolved Vendor Managed Inventory ModelThe use of Vendor Managed Inventory model has gained acceptance in many industries. What was once thought of as an experiment, has now become the preferred way of doing business.

Vendor Managed Inventory Advantages

The Ford Motor Company led by Henry Ford and The Toyota Manufacturing Company led the way to VMI. Cutting the Right Costs with Technology by Sourcing InnovationIn, which advocated that you cut the fat, not the limb, reminded us that there are a number of strategic projects, based on appropriate supply chain technology that can provide a far greater internal rate of return than merely slashing costs. Vendor Managed Inventory and longer-term collaborations offer opportunities for both parties.Further, Fleet Equipment magazine identifies six emerging trends in the dynamic commercial vehicle aftermarket. One of these trends deals with utilizing the latest inventory management techniques to manage customers to “lean”. In addition to more prevalent online ordering, many suppliers now offer Vendor Managed Inventory (VMI). VMI can automatically generate recommended orders based on mutually agreed upon objectives and information sent by the customer.

VMI is an excellent option for many dealers and distributors as it has the ability to increase inventory turns, reduce customer returns, reduce administrative costs and reduce lost sales. VMI is an opportunity for suppliers to refine inventory control for their distribution channels, and ultimately, lower costs to the end user.

We have an ongoing emphasis to continuously improve this channel and streamline the process to make it more effective and responsive.”A real world example of Vendor Managed Inventory in play is electrical products company. Leviton selected a vendor managed inventory solution from VMI specialist as a tool to help them run their business more effectively and giving them a competitive edge by creating a collaborative working relationship with key trading partners. “By moving to Datalliance we are gaining a more robust VMI solution that will better serve the needs of our customers,” said Mark Richards, Leviton’s director of e-commerce. “We also look forward to opportunities to reduce the overall cost and effort of VMI by choosing a more streamlined solution.” What is Vendor Managed Inventory?Vendor managed inventory is a family of business models in which the buyer of a product (business) provides certain information to a vendor (supply chain) supplier of that product and the supplier takes full responsibility for maintaining an agreed inventory the material, usually at the buyer’s consumption location (usually a store). A can also be involved to make sure that the buyer has the required level of inventory by adjusting the demand and supply gaps.As a symbiotic relationship, vendor managed inventory makes it less likely that a business will unintentionally become out of stock of a good and reduces inventory supply chain.

Furthermore, vendor (supplier) representatives in a store benefit the vendor by ensuring the product is properly displayed and store staff are familiar with the features of the product line, all the while helping to clean and organize their product lines for the store.One of the keys to making VMI work is shared risk. In some cases, if the inventory does not sell, the vendor (supplier) will repurchase the product from the buyer (retailer). In other cases, the product may be in the possession of the retailer but is not owned by the retailer until the sale takes place, meaning that the retailer simply houses (and assists with the sale of) the product in exchange for a predetermined commission or profit (sometimes referred to as consignment stock). A special form of this commission business is scan-based trading where VMI is usually applied but its use is not mandatory.This is one of the successful business models used by Walmart and many other big box retailers. Oil companies often use technology to manage the gasoline inventories at the service stations that they supply (Petrolsoft). Home Depot uses the technique with larger suppliers of manufactured goods.